You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boushh Build WIP - Iron's Daughter

- Thread starter Irongladiator

- Start date

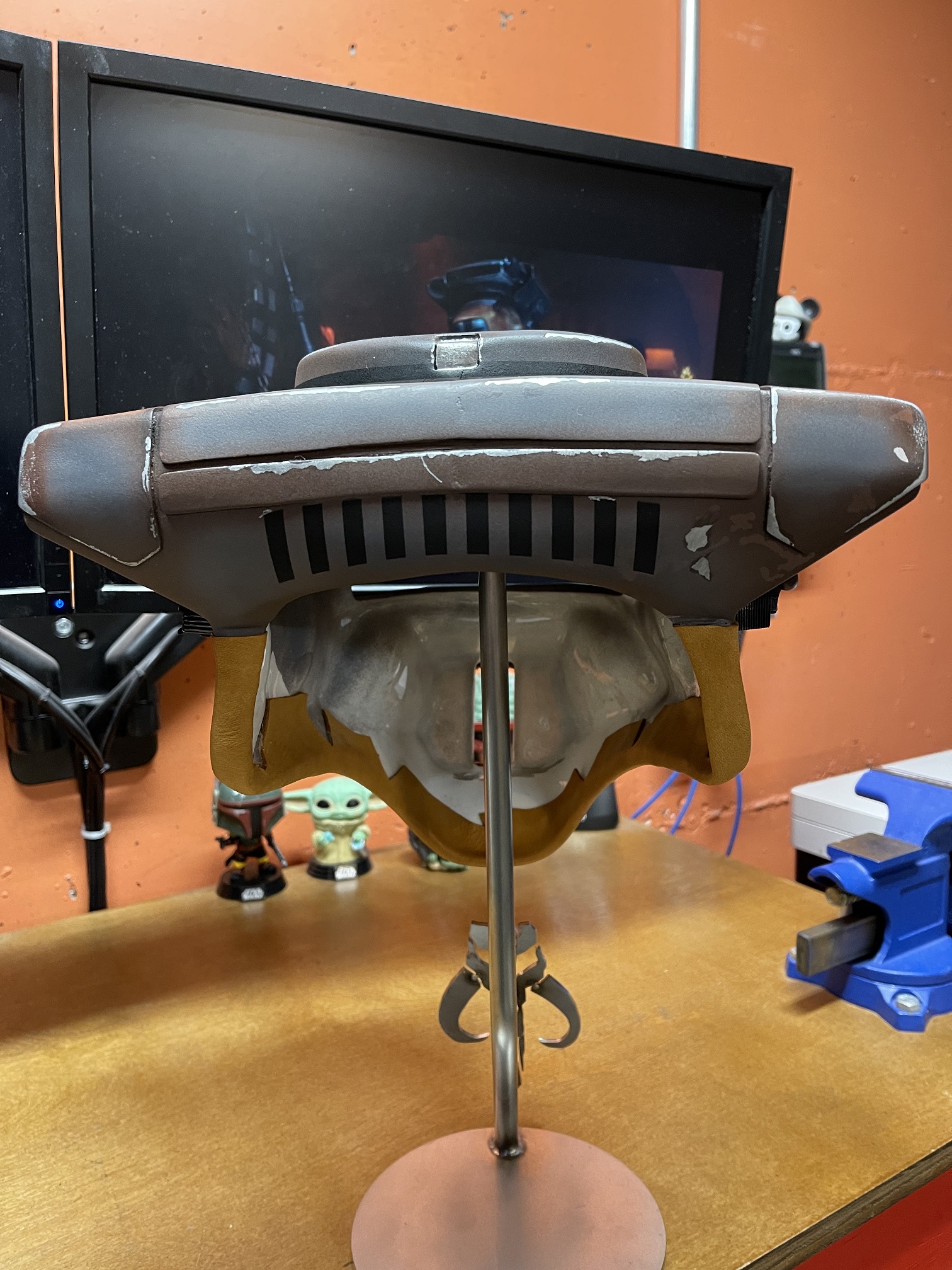

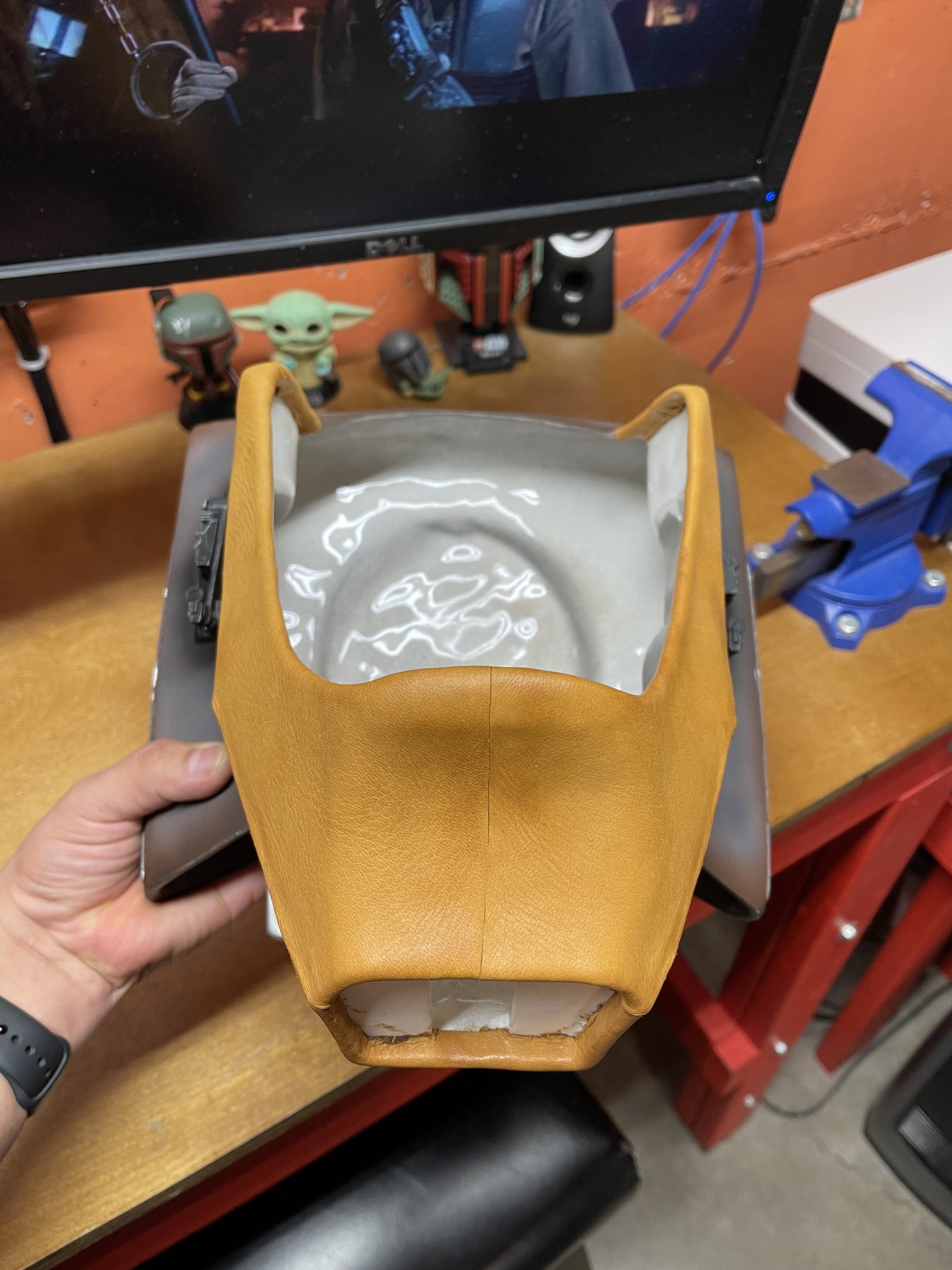

....and so, I'm not entirely done yet, but reached a good stopping point. Armed with a combination of CA Glue, Barge Contact Cement, a brand new X-Acto Blade and new pair of Fiskars Scissors, I was able to get the adhesion of the leather to the Sandman Helmet!

After a few hours of work, here is where I stand with it now!

Thankfully the deer leather is VERY forgiving, I only had one real spot that was a pain in the arse, and the chin, I was worried about having the seams meet up, but all in all I'm very happy with how it turned out and it looks pretty awesome! My kid thinks so too!

There is an extra leather piece that goes around the back of the head and a small leather strap with greeblies, I'll try and have those finished up in the next couple days!

Best,

-Iron

After a few hours of work, here is where I stand with it now!

Thankfully the deer leather is VERY forgiving, I only had one real spot that was a pain in the arse, and the chin, I was worried about having the seams meet up, but all in all I'm very happy with how it turned out and it looks pretty awesome! My kid thinks so too!

There is an extra leather piece that goes around the back of the head and a small leather strap with greeblies, I'll try and have those finished up in the next couple days!

Best,

-Iron

Last edited:

Thanks RBF !Absolutly phenominal work on both paint job and leather work!! Love it!!

Just a tiny update, in that I was able to get the snout finished up and installed!

Little by little, piece by piece, this is coming together. I still have to weather the leather a little bit. Then it is off to get the lenses trimmed and installed. Then comes the electronics installation. After which I'll be able to finish off that back leather piece.

More to follow!

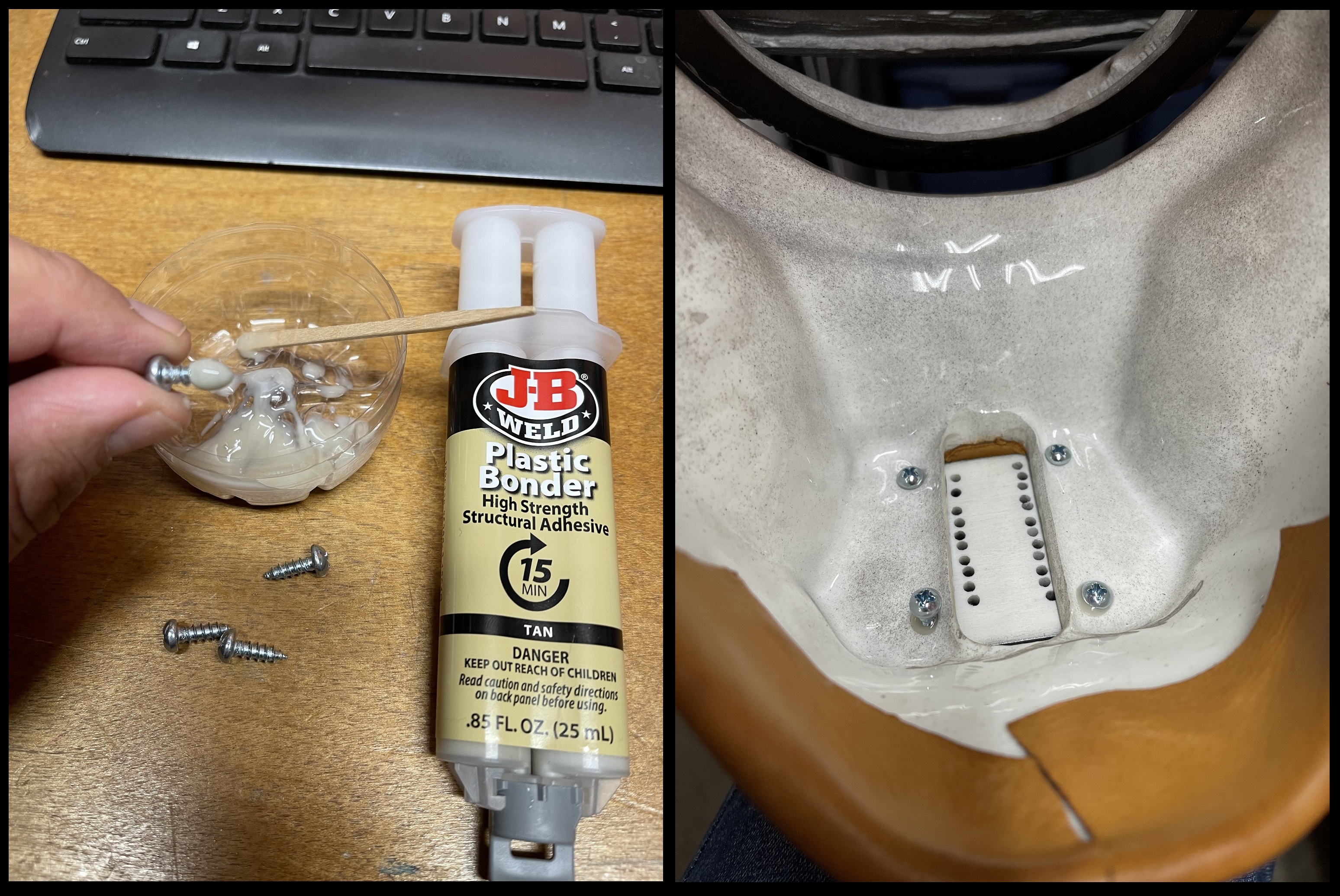

I totally forget to include this pic in my last post. but I wanted to show you what I did to the snout to get it installed....

So for this I simply used a little JB Weld Plastic Bonder (Works with Metal and Plastics!). I used a little bit under the snout piece and then also like how you'd apply Loctite products to keep bolts and nuts from moving - I used a little JB Weld goober'd up on the end of the screw(s) and then screwed the #8 - 1/2 inch Coarse Thread screws into the snout piece. So this is kind of a more permanent solution.

I'm also told this helmet is notoriously warm - which is good if your in cold weather - but I wanna get a fan installed to pull in the outside air from those holes I made in the snout piece - thereby making the helmet more comfortable. I'm fielding any suggestions on that. I'd be looking to power it off of a 9V battery and have it be a silent fan. Kinda like this:

-Iron

So for this I simply used a little JB Weld Plastic Bonder (Works with Metal and Plastics!). I used a little bit under the snout piece and then also like how you'd apply Loctite products to keep bolts and nuts from moving - I used a little JB Weld goober'd up on the end of the screw(s) and then screwed the #8 - 1/2 inch Coarse Thread screws into the snout piece. So this is kind of a more permanent solution.

I'm also told this helmet is notoriously warm - which is good if your in cold weather - but I wanna get a fan installed to pull in the outside air from those holes I made in the snout piece - thereby making the helmet more comfortable. I'm fielding any suggestions on that. I'd be looking to power it off of a 9V battery and have it be a silent fan. Kinda like this:

-Iron

Wicked Fett

Hunter

Dude love the thermal detonator I can’t find one 2013

Thanks Joba FettDude love the thermal detonator I can’t find one 2013

You actually reminded me that I still have to seal it up......I hope this time....nearly 3 weeks later it is cured enough so that it doesn't dull down the chrome effect this time.

-Iron

Last edited:

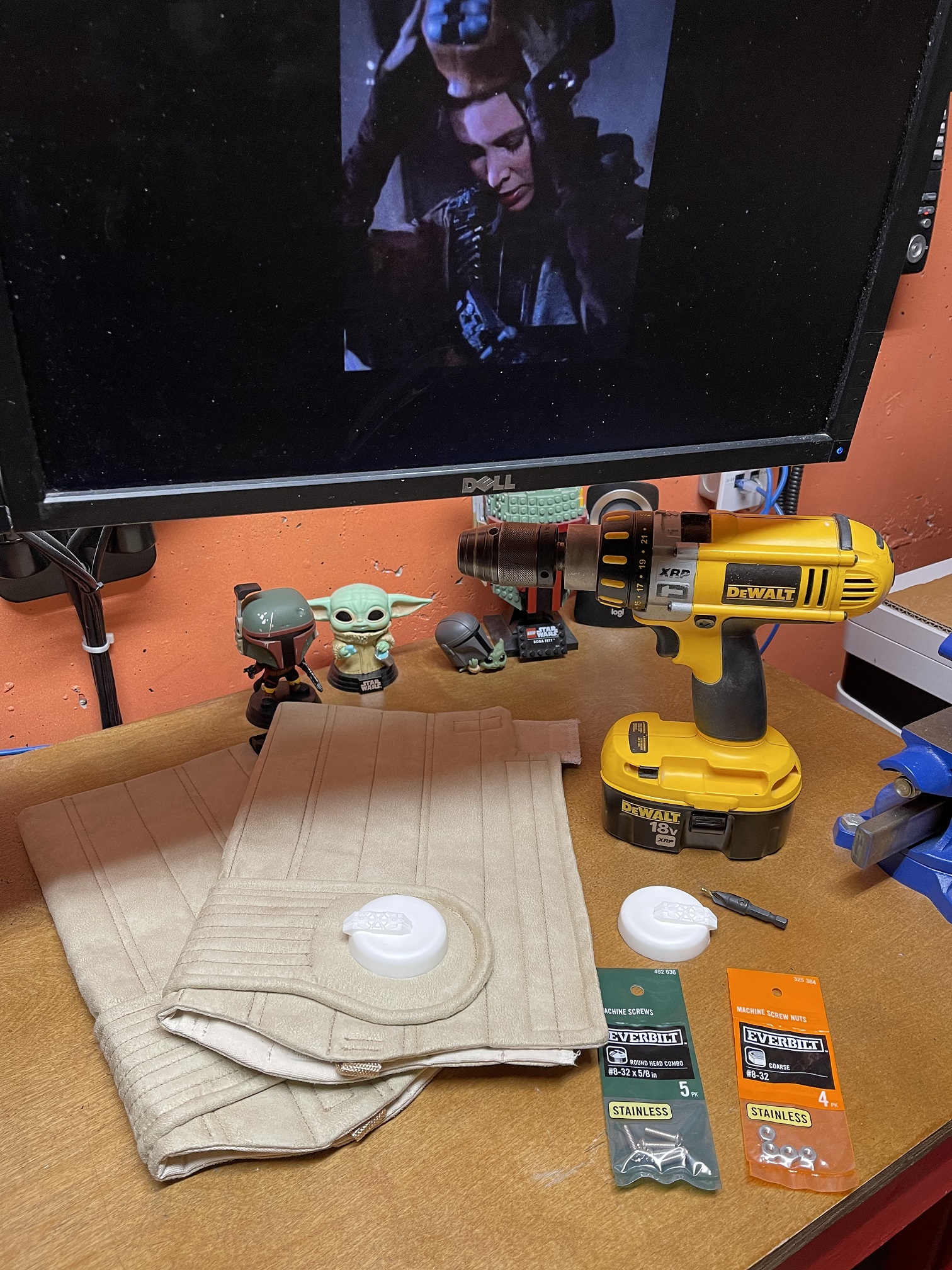

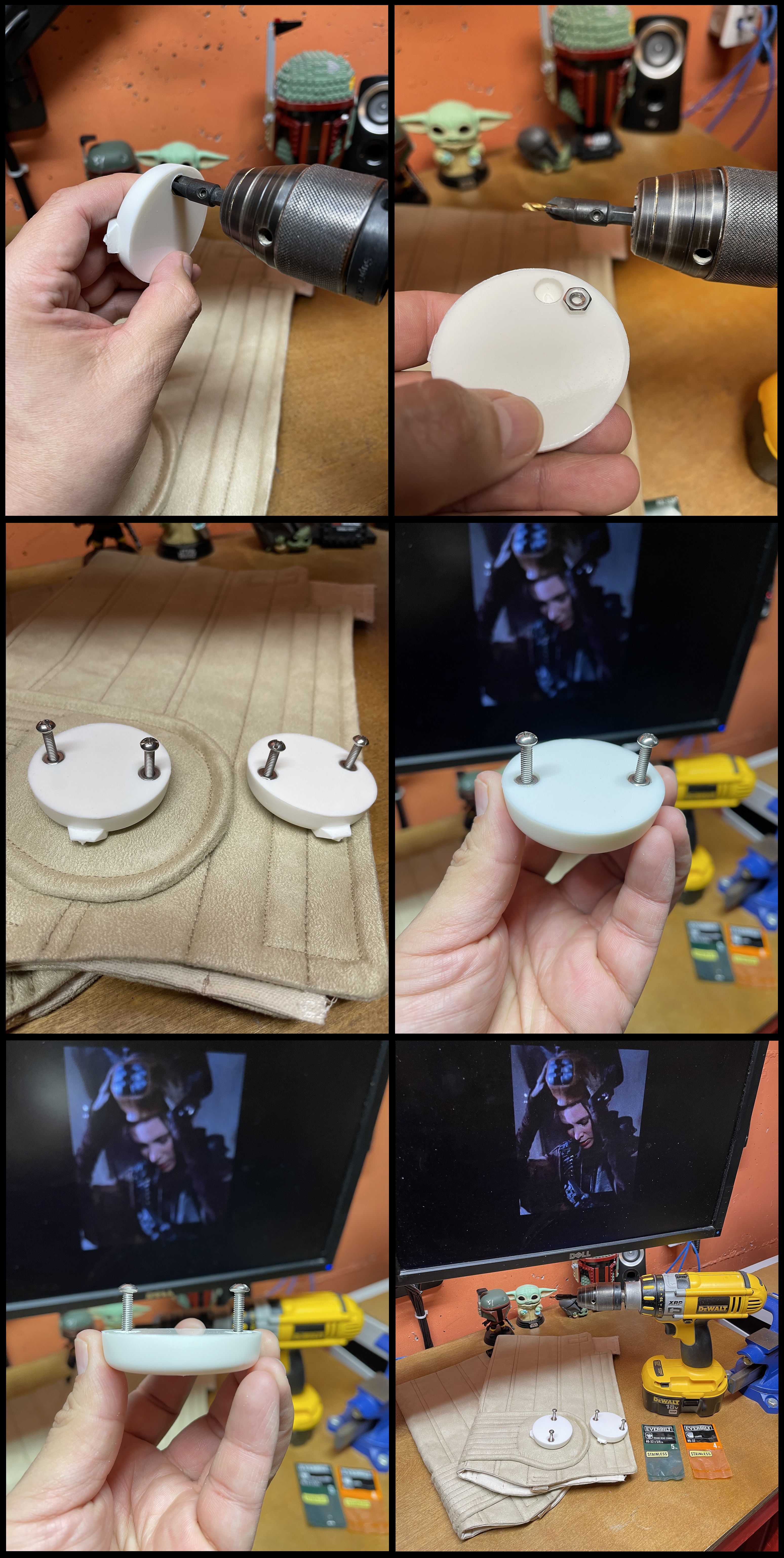

So I caught myself wanting to switch gears here for a moment. And decided to work on the Boot Disc Greeblies a little. I was looking for a way to attach them to the Boot Gaiters/Spats that I got from Alvomedia. I opt'd to have them screwed in, but rather than have a drywall type screw in place I decided to be a bit more creative and wanted to Countersink/Embed in a #8 Hex Nut into the resin greeblie.

And so I began. I started out with my #10 Countersink bit with DeWalt 18v drill. The #8 Hex Nuts and some #8 test screws.

Boring the space out for the hex nuts and placing them was actually really, really easy.

Next step is to very carefully go on the outside edges with some well placed JB Weld Plastic Bonder to ensure the hex nuts do not move when tightened. Then off to some painting the Boot Disc Greeblies and then fitting them to the Boot Gaiters/Spats, and then finally weathering the Boot Gaiter/Spats.

And so I began. I started out with my #10 Countersink bit with DeWalt 18v drill. The #8 Hex Nuts and some #8 test screws.

Boring the space out for the hex nuts and placing them was actually really, really easy.

Next step is to very carefully go on the outside edges with some well placed JB Weld Plastic Bonder to ensure the hex nuts do not move when tightened. Then off to some painting the Boot Disc Greeblies and then fitting them to the Boot Gaiters/Spats, and then finally weathering the Boot Gaiter/Spats.

David Neth

Hunter

Awesome build man! The fan in the snout is the way to go. I have mine going the other direction to vent your breath out. Either way it looks great!

I also love all the mechanical bonds (screws rather than glue). It makes everything so much more serviceable!

I also love all the mechanical bonds (screws rather than glue). It makes everything so much more serviceable!

David NethAwesome build man! The fan in the snout is the way to go. I have mine going the other direction to vent your breath out. Either way it looks great!

I also love all the mechanical bonds (screws rather than glue). It makes everything so much more serviceable!

Thanks man! And yep, that was the idea! I figure for just a little extra effort I can make it so that it is perhaps washable.

-Iron

Another Thermal Detonator Update!

I switched gears a little today as my Thermal Detonator was begging me to get completed. And after talking with another member (rdroid ) on another thread I picked up some Alclad II Aqua Gloss Clear (ALC-600) and sprayed it on my Thermal Detonator and low and behold - worked like a champ! It didn't seem to dull the chrome effect one bit.

In addition, I went to work on the magnet idea. For that I used some super strong rare earth magnets that I had left over from my ROTJ Jetpack's rear access panel. First, I measured and trimmed the stems as needed, as I only needed to fix 6 magnets in place (3 per half). Since JB Weld has not done me wrong yet with these magnets - I used their Plastic Bonder again. And 4 hours later, had achieved a nice strong bond and fits like a glove to boot!

Tomorrow, I'Il get the electronics fit in place!

-Iron

I switched gears a little today as my Thermal Detonator was begging me to get completed. And after talking with another member (rdroid ) on another thread I picked up some Alclad II Aqua Gloss Clear (ALC-600) and sprayed it on my Thermal Detonator and low and behold - worked like a champ! It didn't seem to dull the chrome effect one bit.

In addition, I went to work on the magnet idea. For that I used some super strong rare earth magnets that I had left over from my ROTJ Jetpack's rear access panel. First, I measured and trimmed the stems as needed, as I only needed to fix 6 magnets in place (3 per half). Since JB Weld has not done me wrong yet with these magnets - I used their Plastic Bonder again. And 4 hours later, had achieved a nice strong bond and fits like a glove to boot!

Tomorrow, I'Il get the electronics fit in place!

-Iron

This morning I was able to get the electronics installed....

And the magnets do such a great job in holding it all together. Me and my daughter were even able to play a game of hot potato too before she had to go to school! Here is what it looks like in the light versus darker lighting conditions....

Last step is to weather it up a little. I figure some black with rust colors smudging and smearing it on.

-Iron

And the magnets do such a great job in holding it all together. Me and my daughter were even able to play a game of hot potato too before she had to go to school! Here is what it looks like in the light versus darker lighting conditions....

Last step is to weather it up a little. I figure some black with rust colors smudging and smearing it on.

-Iron

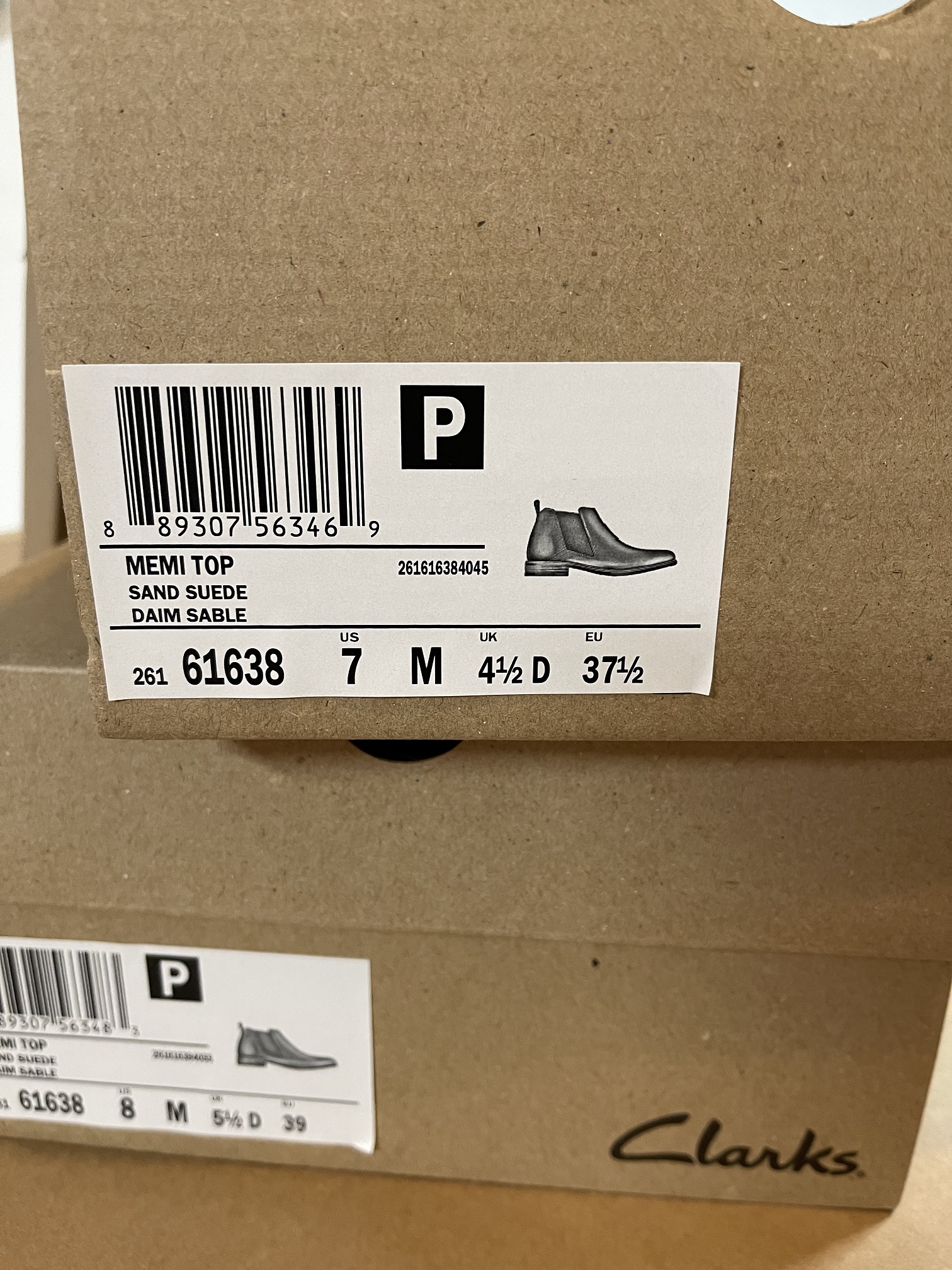

This week I received her boots that I chose. I was mainly concerned with whether or not they would match up against what Alvomedia uses for her Spats/Boot Covers - fabric wise. I dont think they are that bad, and again my daughter is only 10 years old, so she will not be doing 501st anytime soon. But those who know me, know I like to get as close as possible too. I gotta say it is pretty hard to find boots like this. I decided to go with an ankle type of boot only because I didn't wanna have to worry about the length.

For those interested these were $60 and are from Clarks: Memi Top Sand Suede - Clarks® Shoes Official Site | Clarks

They have the same style but are $130 and a tad bit lighter in color, but still not an exact match to Spats/Boot Covers. My thinking is that via weathering and it should blend in ok. But, let me know whatcha think....

Again, I don't think it is too bad - and maybe with some weathering will look even better. Here are the very same ones that they are selling for $130.00 and even though they may look better, do I really spend that extra $70.00?

Best,

-Iron

For those interested these were $60 and are from Clarks: Memi Top Sand Suede - Clarks® Shoes Official Site | Clarks

They have the same style but are $130 and a tad bit lighter in color, but still not an exact match to Spats/Boot Covers. My thinking is that via weathering and it should blend in ok. But, let me know whatcha think....

Again, I don't think it is too bad - and maybe with some weathering will look even better. Here are the very same ones that they are selling for $130.00 and even though they may look better, do I really spend that extra $70.00?

Best,

-Iron

Last edited:

Similar threads

- Replies

- 0

- Views

- 142

- Replies

- 7

- Views

- 176

- Replies

- 1

- Views

- 905

- Replies

- 7

- Views

- 5,816